Christine de Beer - effortless floral craftsman

Casting wet cement to have surface cracks

- 14 February 2013

The goal is to cast the cement in such a way that the surface of the cement dries faster than the sub-surface cement.

Mix up a batch of cement according to the container specifications

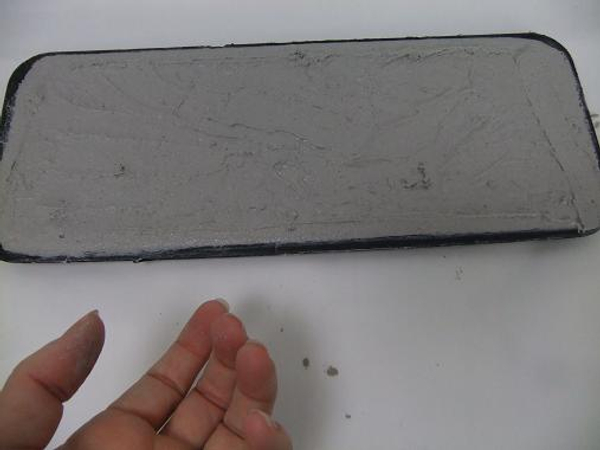

Scoop out the cement into a bowl, tray or mould

Scrape the cement flat

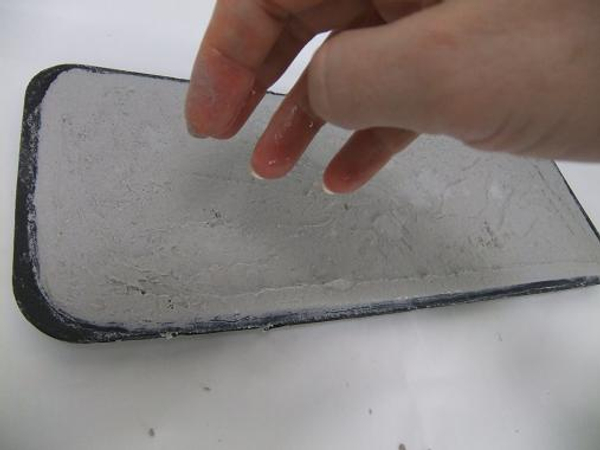

Place the tray on a flat working surface. Lift the cement tray...

And let it drop. This releases any air bubbles stuck in the cement

Continue to lift...

and drop the tray until you no longer see any air bubbles rise to the surface.

Scrape the surface flat.

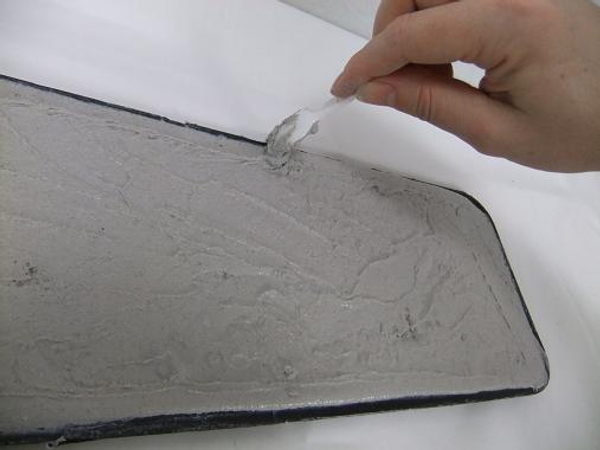

Place your hand in water and sprinkle to water on to the cement tray

Cover the cement tray with plastic and set aside to let the water soak in.

Wait until the water is no longer visible on the surface.

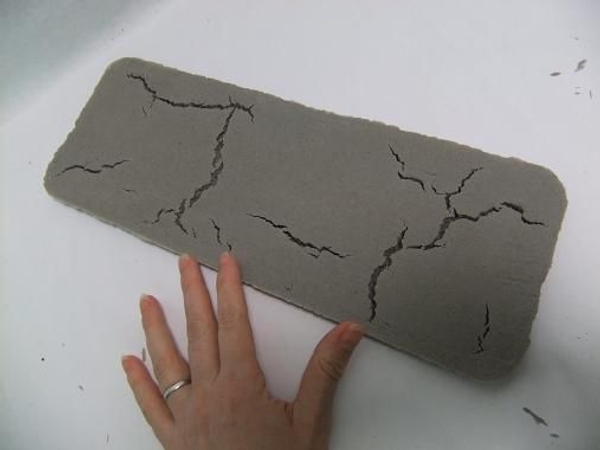

Open the concrete tray and place in a warm, dry area. It normally takes concrete from 5 to 7 days to cure.

It is important to let the cement dry out as fast as possible.

If the surface of the concrete dries faster than the bottom layers, the water from the wet cement will break through the surface and crack the top layer.

The very bottom of the cement tray should dry normal and the cracks will not weaken the structure.

Remove the concrete from the tray

There are no cracks in the bottom of the cement tray...

... but the surface has beautiful cracks ready to fill with moss (see Tutorial below)

Sign up for my weekly newsletter

Every week I add a new design with related tutorials. Be sure to subscribe to receive an email notification with design inspiration.